Machining

line-boring, drilling, milling, flange facing

Industry-independant flexibility, second to none worldwide.

On-site mobile machining brings with it many different challenges. However, every project has one thing in common: no two are alike! That means that in addition to personnel having to be special, the machines used have to be extremely adaptable.

Our extensive range of machinery is actually made up of relatively few different kinds of machines. Yet, each of them can be utilized in the most highly varied ways with the respective workpieces on which they are mounted. Further details regarding our services and mobile machinery offered around the world are listed below. The applications shown, however, only give a small glimpse into the many uses possible. For further details, simply contact one of our contact persons.

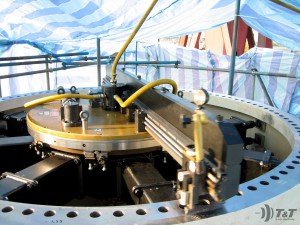

Small pipe flanges or large slewing ring landing faces. It doesn’t matter!

Flanges are essential components of the most diverse assemblies and installations. These may involve simple or high-density pipe connections in the petrochemical industry, support surfaces for sprockets on cranes, or also rolling bearings for the Turret of a FPSO vessel.

It doesn’t really matter what kind of flange we’re talking about. Thanks to the range of machinery available, consisting of five flange-facers and one circular milling machine with a high-precision positioning system we can drill bolt-circles with a broad number of diameters. Onshore, as well as offshore.

And thanks to having all mentioned machines in our own stock (maintained regularly and in perfect condition) there’s no need to rely on the availability of rental equipment. This means all machines are available on short notice to assist you with your project.

The machines mentioned are able to deal with round flanges, however, with our mobile milling machines, of course, rectangular flanges are also no problem. And when the job requires, without time-consuming conversion after boring out a hole with our mobile drilling equipment, we can mill the plane surface in-axis at the appropriate angle.

Our mobile flange processing machines in overview:

Ø0mm | 0″ – Ø200mm | 8″

Ø150mm | 6″ – Ø760mm | 30″

Ø355mm | 14″ – Ø1.143mm | 45″

Ø735mm | 30″ – Ø2.050mm | 80″

Ø1.220mm | 48″ – Ø3.048mm | 120″

Ø2.500 – Ø6.500mm

Ø1.524 | 60″ – Ø4.064mm | 160″

More machines already in development!

- coal mills

- slewing ring landing faces

- GSO flanges

- pipe flanges

- rolling bearing landing faces

- head flanges

Flange facing of a slewing ring landing face on a crane.

The AX48/120 machines flanges diameter 1.200mm up to 3.500mm through turning.

After a maximum time of 10-12 hours one flange in a commom diameter of 3.000mm is machined completely machined. Overall flatness after machining: 0,12mm.

The machine comes in two wooden boxes and weighs in total approx. 1.900kgs. Every common transportian method (airfreight, truck, vessel…) can be used to get the machine on every location all over the world. Thanks to our shipping partners the machine can be on it’s way within 24 hours (Time can differ in reference to specific regulations of some countries).

Machining of two flanges, Ø6.000mm each, with the circular mill FFM6500.

Overall flatness after machining: 0,17mm and 0,16mm.

Machining of both flanges within 24 hours.

Even though the machine weighs approx. 6.5 tons, separated in four wooden cases, the FFM6500 can be shipped with all common transportation method and used worldwide.

Boring out small bolts? Spindling of larger bore holes?

The right machine is ready for each job!

Continuous machining of Ø 35mm – Ø 2.000mm with just three different machines!

In addition to normal spindle work, without a lot of modifications the same machines can make cones, mill surfaces, or groove circumferential slots. Only the rotating arm has to be replaced. Thus, the necessary processing and equipment downtimes are drastically reduced.

Because, as a rule, only one kind of machine is needed for a job, freight costs are kept as low as possible. Only those parts are sent which will actually be used on-site; no accessories or add-on components which will not specifically be used to accomplish the work are chosen.

Our mobile drilling devices in overview

The little one.

Ø35mm – Ø70mm

- drilling out of bolts

- line-boring for fitting bolts

The all-rounder.

Ø90mm – Ø1.000mm

- drilling out of bolts

- line-boring for fitting bolts

- solid drilling

- back facing

- bearing seats on rudder and propulsion systems

- line-boring of main bearing pockets

- (flange-)facing

- line boring of conical bores

The new one.

Ø1.000mm – Ø2.000mm

- drilling out of bolts

- line-boring for fitting bolts

- solid drilling

- back facing

- bearing seats on rudder and propulsion systems

- line-boring of main bearing pockets

- (flange-)facing

- line boring of conical bores

Proven technology newly interpreted.

Linear conductors and recirculating ball screws are only two terms common to our technical status quo.

Two machine beds set up exactly alike in two different lengths are enough to cover an endless number of possibilities for mobile milling operations. Thanks to the use of laser measurement technology, we manage to create a virtual reference level before the work begins in which our machines can configure time and again. Thus, putting the milling machine into operation on a large machine foundation becomes very simple.

Horizontally, vertically, or over the head, the position of the machine doesn’t matter. The choice of chucking is made in close cooperation with our customers, depending on the on-site requirements in accordance with material specifications, and, if necessary, by us, our partners, or by our customers themselves.

An overview of our mobile milling machines

1.500mm bedplate

2.500mm bedplate

- bridge sections

- foundations / supports

- press guides

- glideways

- joints

- guides

powered by knowledge

powered by knowledge