Much knowledge and the right equipment are the essential parts, which are needed to offer fast, cost effective and highly accurate services all over the world.

The Nordseewerke in Emden | Germany rely on T&T In Situ Machining GmbH.

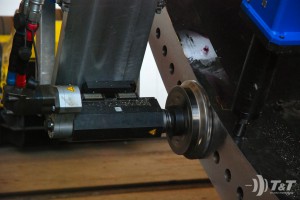

Within 24 hours two flanges of a tower segment were machined with our circular mill CM6200. The overall flatness of the two flanges in a diameter of 6.000mm each was at 0,17mm and 0,16mm.

The perfect situation for all downstream operations of the segment.

Taking a service provider for this works is a highly efficient solution for the Nordseewerke. Own engineers and technicians can be taken for other projects. The result is increasing productivity.

The machines weighs approx. 6.5 tons. However handling is for our specialists a child’s play.

It takes just a few hours to assemble the machine, mount it on the workpiece and align it for machining. They only thing they need is a crane.

And thanks to the extreme flexibility our solutions can be planned easily in a mass production.

We thank the Nordseewerke for the excellent cooperation and look forward to upcoming projects.

powered by knowledge

powered by knowledge